From Chaos to Control: How Supply Chain Software Maximizes Productivity

21 Apr 2024 • 29 min read

Marcin Kulawik

Sustainability isn't achievable without a sustainable supply chain. A staggering 85% of a company's environmental, social, and governance (ESG) impact comes from its supply chain, with emissions from products and services exceeding 90%. Transforming this critical network is essential for real progress.

The good news is, businesses are recognizing this. Nearly half have set goals for supply chain sustainability, and a significant 70% are looking to invest in circular economies that prioritize reuse and recycling to minimize waste. This article provides actionable steps to make your own business more sustainable.

What is a SCM software system?

SCM (Supply Chain Management) software is your digital backbone for optimizing supply chain operations. These comprehensive systems go beyond simple visibility; they offer real-time data, analytics, and automation to empower smarter decision-making across the entire chain.

Think of your supply chain as a complex network. SCM software acts as the central control hub, integrating modules that manage various critical functions:

- Demand Forecasting: Gone are the days of gut feeling. Advanced AI and machine learning in SCM software can predict demand fluctuations with incredible accuracy, allowing you to optimize production and procurement.

- Collaborative Sourcing: Today's SCM platforms facilitate seamless communication and collaboration with suppliers. Streamline the entire process, from issuing purchase orders to tracking order status in real-time.

- Intelligent Inventory Management: Never again get caught with too much or too little stock. Modern SCM software utilizes data analytics to suggest optimal inventory levels and automates replenishment processes.

- Agile Manufacturing: Adapt and thrive in a changing market. SCM software helps with production scheduling, resource allocation, and quality control, ensuring efficient and flexible manufacturing.

- End-to-End Logistics Visibility: Track your goods in real-time, from the moment they leave your supplier to the moment they reach your customer. Modern SCM offers complete shipment tracking and facilitates seamless logistics management.

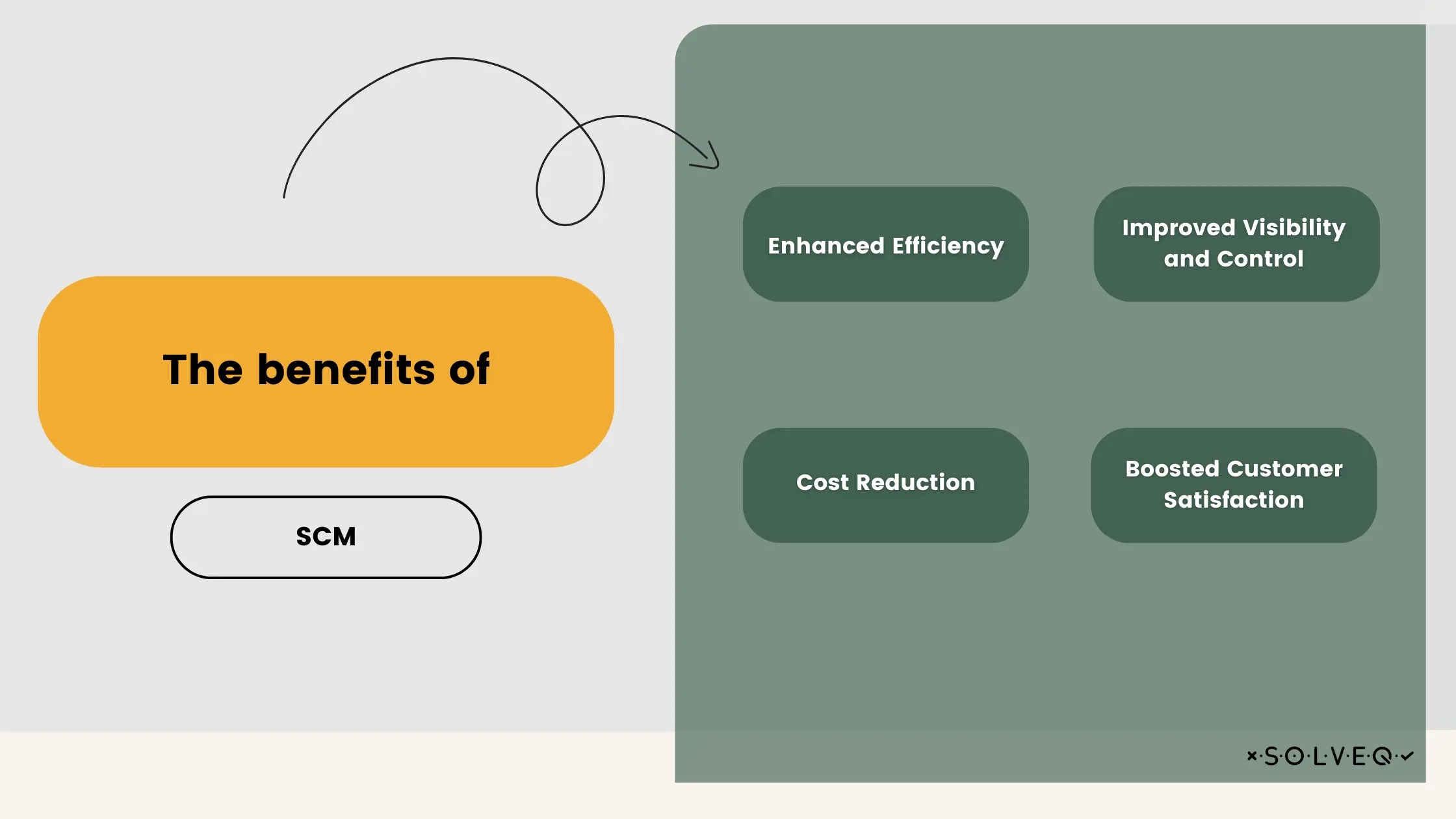

The benefits of SCM software are undeniable. Businesses can expect:

- Enhanced Efficiency: Automate manual tasks, streamline processes, and optimize resource utilization.

- Cost Reduction: Reduce waste, optimize inventory levels, and negotiate better deals with suppliers.

- Improved Visibility and Control: Gain real-time insights across your entire supply chain, allowing for proactive decision-making.

- Boosted Customer Satisfaction: Reliable deliveries, accurate inventory levels, and faster response times lead to happier customers.

By implementing a robust SCM software system, you're investing in a more resilient, efficient, and ultimately, sustainable supply chain – a key differentiator in today's competitive market.

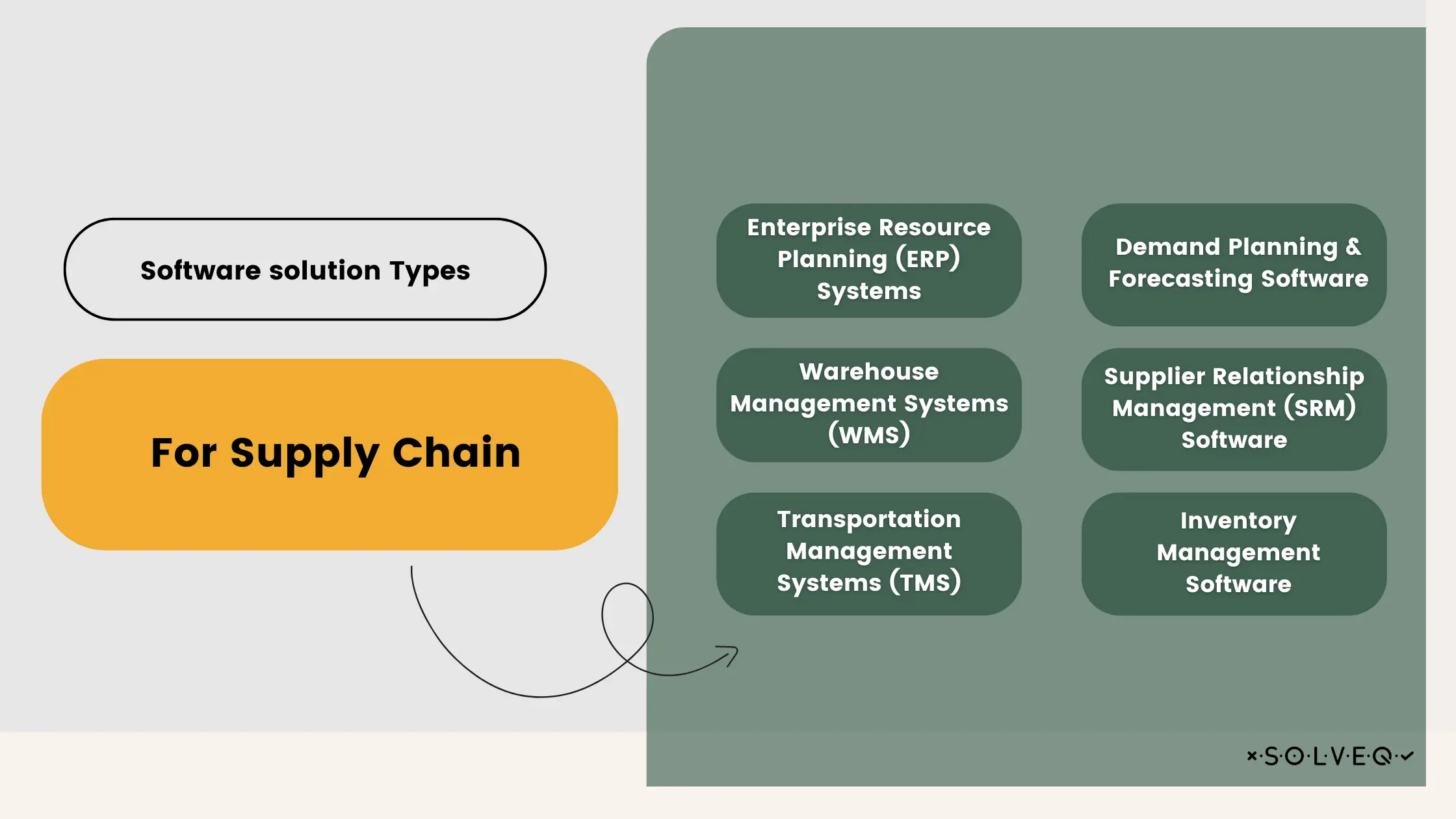

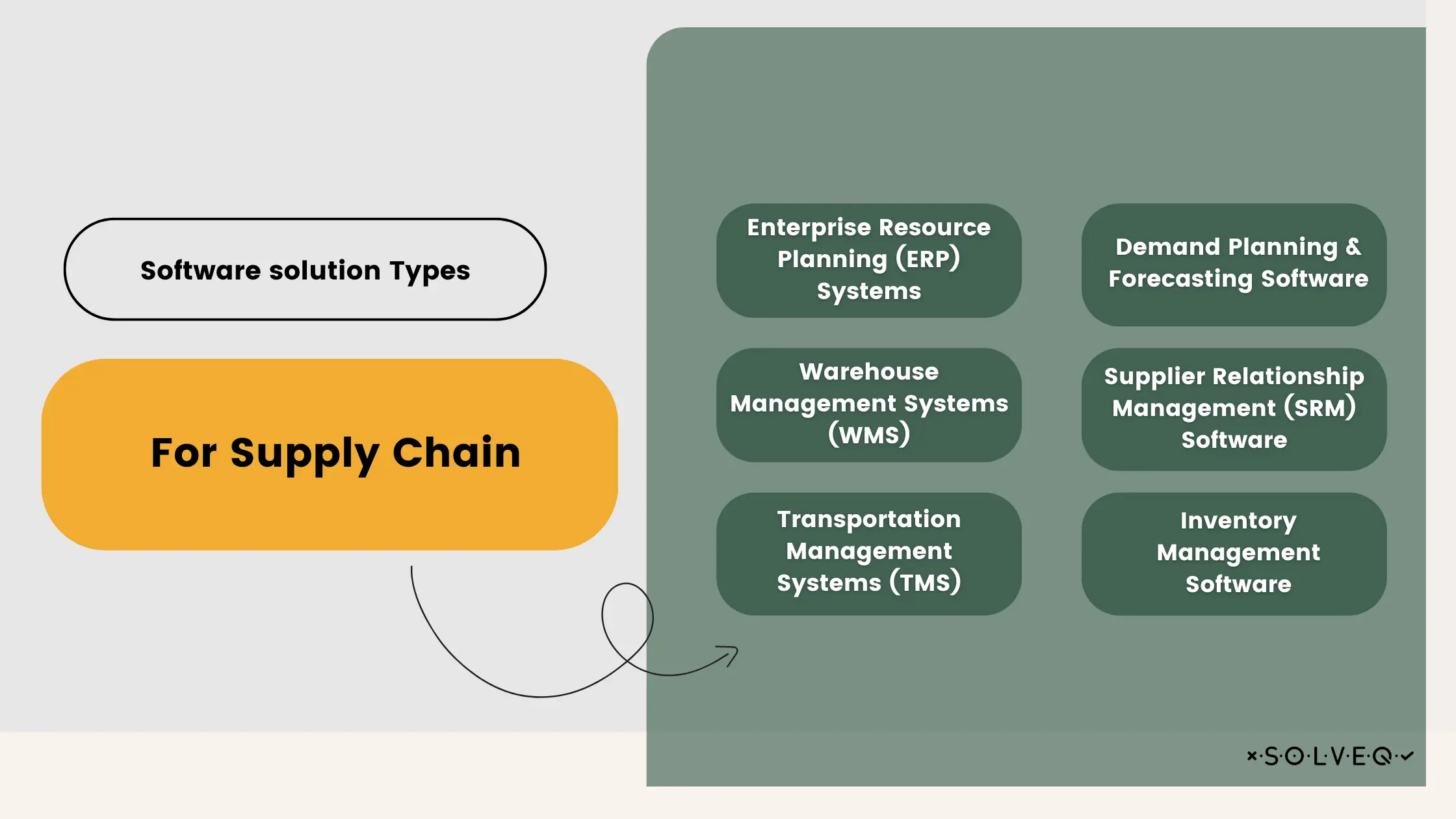

Software solution Types For Supply Chain

The one-size-fits-all approach doesn't work in supply chain management. Today's businesses have a diverse toolbox of specialized software solutions to tackle specific challenges and optimize their unique operations.

Let's explore some of the key players:

- Enterprise Resource Planning (ERP) Systems: Think of your ERP as the central nervous system of your business. It integrates all core functions, including supply chain management. Benefits include seamless data flow, automated tasks, and real-time insights for better decision-making.

- Warehouse Management Systems (WMS): Your warehouse is the heart of your supply chain. WMS software is specifically designed to optimize warehouse operations and inventory control. Expect improved accuracy, increased efficiency, and ultimately, happier customers who receive their orders faster.

- Transportation Management Systems (TMS): Ensure your goods move smoothly and efficiently. TMS software takes care of transportation planning, execution, and real-time tracking. This translates to better visibility across your supply chain, reduced shipping costs, and optimized delivery times.

- Demand Planning & Forecasting Software: Don't get caught off guard by fluctuating demand. Advanced demand planning and forecasting software utilizes AI and machine learning to predict future needs with incredible accuracy. This allows you to optimize inventory levels and avoid stockouts or overstocking.

- Supplier Relationship Management (SRM) Software: Strong supplier relationships are essential for a resilient supply chain. SRM software fosters collaboration and communication with your vendors, streamlining procurement processes and minimizing risks.

- Inventory Management Software: Never lose track of your stock again. Inventory management software goes beyond basic tracking. It leverages data analytics to suggest optimal inventory levels and automates replenishment, ensuring you have the right products in stock at the right time.

By strategically selecting the most appropriate software solutions, businesses can achieve:

- Enhanced Efficiency: Streamline processes, automate tasks, and optimize resource allocation from warehouse to delivery.

- Reduced Costs: Gain better visibility into spending, negotiate with suppliers more effectively, and minimize inventory waste.

- Improved Customer Satisfaction: Deliver orders faster and more reliably, keeping your customers happy and coming back for more.

Remember, the best SCM software isn't a magic bullet; it's a powerful tool that empowers informed decision-making and propels your business towards a more efficient, customer-centric, and ultimately, successful supply chain.

Four Key Approaches to Supply Chain Management

Supply chain management is a dynamic field, and a "one-size-fits-all" approach simply doesn't work. Companies leverage various strategies to tackle specific challenges and optimize their operations. Let's explore four prominent approaches:

- Harmonious Supply Chain Management: Imagine your supply chain as a well-oiled machine. Harmonious management prioritizes seamless collaboration between everyone involved, from suppliers to customers. By fostering information sharing, synchronized activities, and unified goals, this approach boosts efficiency and keeps customers happy.

- Dynamic Supply Chain Management: Agility is key in today's ever-changing market. Dynamic management emphasizes rapid adaptation to evolving customer needs and market trends. Think flexible manufacturing, swift product development, and real-time response to demand fluctuations. This approach aims to minimize lead times, elevate customer service, and gain a competitive edge through speed and flexibility.

- Efficient Supply Chain Management: "Lean and mean" is the motto here. Efficient management focuses on eliminating waste and minimizing costs without sacrificing quality. This model prioritizes inventory reduction, process streamlining, and continuous improvement. By implementing lean practices like just-in-time production, companies can fine-tune their supply chain and maximize customer value.

- Sustainable Supply Chain Management: Going green is no longer optional. Sustainable management, also known as eco-friendly, considers the environmental, social, and ethical impact of the supply chain. This approach focuses on reducing carbon footprint, minimizing waste, prioritizing ethical sourcing and fair labor practices, and advocating for responsible product disposal. It aligns with the principles of sustainability and corporate social responsibility.

It's important to remember that these approaches aren't mutually exclusive. Companies can often combine elements from different models to create a hybrid strategy that best suits their specific needs and goals. Furthermore, technological advancements like digital supply chain management and the principles of a circular economy are shaping the future of this ever-evolving field.

How Real-Life Businesses Leverage SCM Software

You've learned about the different types of SCM software and their potential benefits, but how do these translate to real-world results? Here are some inspiring examples:

Nike: Stepping Up for Sustainability

- Challenge: Balance efficiency with environmental responsibility and ethical sourcing practices.

- Solution: Nike partnered with LLamasoft to gain data-driven insights and identify areas for improvement in their supply chain's sustainability.

- Results: Reduced carbon emissions, minimized waste, increased overall efficiency, and a stronger alignment with their commitment to a sustainable future.

Walmart: Optimizing Inventory Management for Maximum Availability

- Challenge: Maintain optimal stock levels across a vast network of stores to avoid stockouts and unnecessary storage costs.

- Solution: Walmart utilized JDA software for sophisticated demand forecasting and inventory management.

- Results: Reduced costs, improved product availability for customers, and increased overall customer satisfaction.

Unilever: Building Agility in a Dynamic Market

- Challenge: Maintain high service levels and customer satisfaction despite unexpected disruptions or market fluctuations.

- Solution: Unilever implemented Kinaxis software for real-time data visibility and enhanced agility in managing their supply chain.

- Results: Swift response to disruptions and demand changes, consistent high service levels, and satisfied customers even in a dynamic marketplace.

These are just a few examples of how companies across industries are leveraging SCM software to achieve significant results. By implementing the right solutions, businesses can optimize efficiency, reduce costs, enhance customer satisfaction, and even achieve their sustainability goals.

Top Supply Chain Management Solutions for 2024

In today's dynamic business landscape, efficient supply chain management is no longer an option – it's a necessity. Supply chain management (SCM) software empowers companies of all sizes to plan, execute, and track their supply chain operations with greater precision, leading to significant improvements. Here are some of the leading SCM software solutions in 2024, chosen based on factors like robust features, competitive pricing, exceptional support, and a commitment to innovation:

SAP Ariba

This cloud-based solution remains a powerhouse in procurement and supply chain management. SAP Ariba offers a comprehensive suite of features including supplier management, strategic sourcing, contract management, and seamless supplier collaboration, all designed to streamline and optimize your supply chain processes.

Oracle Supply Chain Management (SCM) Cloud

Oracle's SCM Cloud continues to provide businesses with end-to-end visibility and control over their supply chain. This robust platform includes modules for demand planning, inventory management, logistics, order fulfillment, and supplier collaboration. In 2024, expect to see Oracle focus on further integrating emerging technologies like artificial intelligence (AI) and machine learning (ML) to deliver even greater supply chain optimization.

Blue Yonder (formerly JDA Software)

As part of the Blue Yonder rebrand, JDA Software continues to offer industry-leading supply chain planning and execution solutions. Their software empowers businesses with advanced capabilities in demand forecasting, inventory optimization, production planning, transportation management, and warehouse management, ensuring an efficient and responsive supply chain.

Coupa

Coupa's comprehensive spend management platform goes beyond basic procurement. It offers a unified solution encompassing procurement, invoicing, and expense management, allowing organizations to automate processes, manage supplier relationships effectively, and gain valuable insights into their spending data for smarter decision-making.

Ivalua

This unified source-to-pay platform continues to be a strong contender in the market. Ivalua offers a comprehensive suite of features that cover the entire procurement lifecycle, including supplier management, strategic sourcing, contract management, procurement analytics, and supplier collaboration. In 2024, expect Ivalua to focus on helping businesses leverage advanced analytics to optimize sourcing strategies and drive superior supplier performance.

Choosing the Right Solution:

Finding the perfect SCM software solution depends on your unique business needs and goals. Carefully evaluate your specific requirements, budget, and desired level of functionality before making a decision. Remember, the best SCM software is an investment in your company's future, empowering you to build a more resilient, efficient, and ultimately, successful supply chain.

The Benefits of SCM Software

We've established the potential of SCM software, but how can it truly benefit your business? Here's a closer look at the advantages you can expect:

Real-Time Visibility and Transparency

Imagine having a crystal ball for your supply chain. Modern SCM software offers this level of transparency, providing real-time insights across your entire network, from sourcing to delivery. Track inventory levels, monitor shipments in transit, and evaluate supplier performance – all in one place. This allows for proactive problem-solving, pinpointing bottlenecks and inefficiencies before they disrupt your operations.

Optimized Inventory Management

Never get caught with too much or too little stock again. SCM software utilizes advanced demand forecasting and inventory planning modules to anticipate future needs and ensure optimal inventory levels. Automated replenishment and order management features eliminate the risk of stockouts or overstocking, keeping your costs in check and your customers happy.

Seamless Supplier Collaboration

Managing a network of suppliers can be a challenge. SCM software streamlines this process by fostering seamless collaboration. Features like electronic data interchange (EDI) and supplier portals enable smooth communication, expedite order fulfillment, and provide real-time visibility into supplier performance. This translates to a more efficient supply chain and stronger partnerships with your suppliers.

Automated Warehouse Operations

Transform your warehouse into a well-oiled machine. Many SCM solutions integrate warehouse management systems (WMS) that automate tasks like inventory tracking, pick-and-pack optimization, and barcode scanning. These features not only improve order accuracy and reduce labor costs, but also boost overall warehouse efficiency and operational productivity.

Data-Driven Decision Making with Analytics and Reporting

Data is the lifeblood of successful supply chain management. SCM software gathers and analyzes vast amounts of data, providing valuable insights to inform strategic decisions. Real-time reporting, customizable dashboards, and key performance indicators (KPIs) allow you to continuously monitor your supply chain's performance, identify areas for improvement, and ensure you're on track to achieve your business objectives.

By implementing a robust SCM software solution, you're investing in a more transparent, efficient, and ultimately, data-driven supply chain – a key competitive advantage in today's dynamic business landscape.

Essential Features of SCM Software

Choosing the right SCM software is crucial for building a robust and efficient digital supply chain. Here are eight key features to prioritize:

- Seamless Integrations: A well-connected supply chain is a powerful one. Look for software that integrates seamlessly with your existing systems (ERP, CRM, etc.) to ensure smooth information flow and eliminate data duplication.

- Real-Time Collaboration: Communication is key! Effective SCM software facilitates real-time collaboration among all stakeholders, including suppliers, partners, and internal teams. This fosters transparency and empowers everyone to work together efficiently.

- AI-Powered Process Optimization: Automate tedious tasks and unlock new levels of efficiency with AI and machine learning. Modern SCM software utilizes these technologies to streamline processes, reduce manual intervention, and optimize your supply chain for peak performance.

- Advanced Analytics and Forecasting: Data is your most valuable asset. The chosen SCM software should offer robust analytics and forecasting capabilities. This allows you to evaluate performance, identify bottlenecks, anticipate future demand trends, and make data-driven decisions that optimize your supply chain.

- Customizable Solutions: No two businesses are identical. Your SCM software should be adaptable to your unique needs. Look for solutions that offer pre-built components and customizable configurations to tailor the system to your specific workflows and requirements.

- Cloud-Based Accessibility: Embrace the flexibility of the cloud. Cloud-based SCM software allows for remote management of transactions, facilitating faster deployment and cost-effectiveness compared to traditional on-premise solutions. Plus, it provides anytime, anywhere access for authorized users.

- Uncompromising Security: Security is paramount. The chosen SCM software should prioritize data protection with features like encryption, virus scanning, and robust network monitoring. Ensure the software also complies with relevant data privacy and communication standards.

- Scalability for Growth: Your business is dynamic, and your SCM software should be too. A scalable solution can accommodate growth, handle increased transaction volumes, and support integration with multiple applications and channels without compromising performance. This ensures your supply chain remains efficient and adaptable as your business expands.

By focusing on these essential features, you can select the right SCM software to build a powerful digital supply chain that empowers your business for long-term success.

8 Cutting-Edge Technologies Revolutionizing Supply Chains

The global supply chain landscape is undergoing a dramatic transformation. Cutting-edge technologies are reshaping how businesses manage their operations, optimize efficiency, and gain a competitive edge. Let's explore eight of the most impactful advancements:

5G

Supercharged Connectivity and Real-Time Visibility: Imagine a supply chain with near-instantaneous communication and data exchange. 5G technology delivers this reality. By harnessing its power, organizations can enhance network connectivity, optimize collaboration across the supply chain, and gain real-time visibility into operations. Think smart sensors embedded with 5G capabilities, collecting and analyzing data throughout the entire supply chain journey. This allows for precise tracking of goods, remote monitoring of environmental conditions, and proactive problem-solving. Leading companies like Intel, Nokia, and Samsung are at the forefront of this revolution.

Augmented and Virtual Reality (AR/VR)

Reimagining Warehousing and Decision-Making: AR and VR are no longer just for entertainment. These technologies have the power to transform supply chain operations. AR allows for the creation of virtual stockrooms, where employees can access product information and make informed decisions about picking and storage – all without physically handling items. VR, on the other hand, enables simulation of complex supply chain scenarios, allowing for better planning and risk mitigation. Companies like ScienceSoft and PTC are leading the way in this exciting space.

Autonomous Vehicles

The Future of Delivery: Self-driving trucks and drones are poised to disrupt the transportation sector. By incorporating autonomous vehicles into the supply chain, organizations can achieve significant cost savings and improve delivery times. These intelligent vehicles minimize human error, optimize routes, and operate 24/7. Leading companies like TuSimple and Uber Freight are pioneering this technology, with solutions like autonomous truck platoons that leverage aerodynamics to conserve fuel.

Big Data and Analytics

Data-Driven Decisions for a Smarter Supply Chain: The power of big data is undeniable. By harnessing vast amounts of information and employing advanced analytics tools, organizations can gain deeper insights into their supply chains. This empowers them to make data-driven decisions regarding procurement, risk management, and Sales & Operations Planning (S&OP).

Robotic Process Automation (RPA)

Automating Repetitive Tasks for Enhanced Efficiency: Repetitive tasks are a thing of the past with RPA. This technology automates manual processes, freeing up human workers to focus on more strategic initiatives. In warehousing and manufacturing, robots are transforming operations by increasing speed and accuracy, reducing errors, and minimizing the time required for tasks like picking and sorting. Companies are also exploring the potential of robots for last-mile delivery solutions.

Internet of Things (IoT)

The Networked Supply Chain: The Internet of Things (IoT) is a game-changer. Billions of connected devices embedded in everything from sensors to machinery are transforming how data is collected and utilized. This interconnected network allows for real-time data exchange, enabling organizations to track materials, monitor equipment performance, and optimize efficiency throughout the supply chain. Leading companies like Siemens and Cisco are at the forefront of IoT innovation.

Cloud Computing

Scalability, Flexibility, and On-Demand Access: Cloud computing provides a robust platform for storing and processing vast amounts of supply chain data. This technology offers scalability, flexibility, and cost-effectiveness compared to traditional on-premise solutions. Organizations can access data from anywhere, at any time, empowering them to make informed decisions quickly. Cloud computing encompasses various models like Software-as-a-Service (SaaS) – a popular choice for supply chain management software.

Blockchain

Ensuring Transparency and Security: Blockchain technology offers a secure and transparent way to track goods and products throughout the supply chain. This distributed ledger system records every transaction, providing a tamper-proof record of movement and ownership. Blockchain addresses the growing need for transparency and sustainability in supply chains, helping to combat fraud and errors. Companies like IBM and Ethereum are leading the way in this transformative technology.

By embracing these cutting-edge technologies, businesses can build a more resilient, efficient, and data-driven supply chain, gaining a significant competitive advantage in today's dynamic global marketplace.

Finding the Perfect Fit: Buy, Build, or Subscribe to Your SCM Solution?

Selecting the right supply chain management (SCM) software is a critical decision that shouldn't be rushed. This choice impacts every department, not just operations, and can have a significant long-term impact. Here's a breakdown of the three main approaches to consider, along with factors to help you choose the best fit for your business:

Buy (Traditional On-Premise Solutions)

Pros:

- Established integration processes with common ERP systems.

- High degree of customization to meet specific needs.

- Potential for ownership and control over the software.

Cons:

- Often expensive due to customization needs and lengthy onboarding.

- Requires additional investment for maintenance, infrastructure, and ongoing support.

- May not be as scalable as cloud-based solutions.

Build (Developing Your Own System):

Pros:

- Tailored to your exact requirements and workflows.

- Potential for long-term cost savings (depending on development and maintenance costs).

Cons:

- Requires significant resources and expertise in software development and infrastructure management.

- Integration with existing systems can be complex and costly.

- Time-consuming development process can delay implementation.

- May lack the ongoing updates and feature enhancements offered by commercial solutions.

Subscribe (Cloud-Based Solutions):

Pros:

- Affordable and scalable, with flexible pricing options.

- Cloud-based deployment eliminates the need for on-premise infrastructure.

- Regular updates and continuous improvement based on shared user feedback.

- User-friendly interfaces and readily available customer support.

Cons:

- May not offer the same level of customization as on-premise solutions.

- Reliant on internet connectivity for access and functionality.

Choosing the Right Path

The ideal solution depends on factors like your company size, budget, technical expertise, and specific needs. Here are some additional considerations:

- Complexity of your supply chain: For intricate operations, a customizable buy or build option might be preferable. For simpler needs, a subscription solution might suffice.

- Technical resources: Building an SCM system requires significant in-house expertise. If this is lacking, consider buy or subscribe options.

- Scalability needs: Subscription models offer easy scaling as your business grows. On-premise solutions might require additional investment for upgrades.

- Budget: Subscription models often have lower upfront costs compared to buying or building.

By carefully evaluating your needs and resources, you can make an informed decision and select the SCM software solution that empowers your business for long-term success.

Summary

Supply chain management (SCM) software is a game-changer for sustainable business practices. It optimizes logistics, reducing a company's environmental footprint. Additionally, SCM software streamlines operations, cuts waste, and saves money. Following the lead of companies like Coca-Cola, businesses can leverage SCM software for both sustainability and cost savings. There are three options for acquiring SCM software: buying a customizable system, building your own (with significant investment), or subscribing to a cloud-based solution. Choosing the right approach empowers businesses for long-term success.

Share:

Looking for expert development team?

Schedule a call with Tech Consultant

Marcin Kulawik

Founder and CEO of SolveQ. Huge fan of building things with purpose, agility, and having fun while changing the World. Loves his family, teammates, and nature.